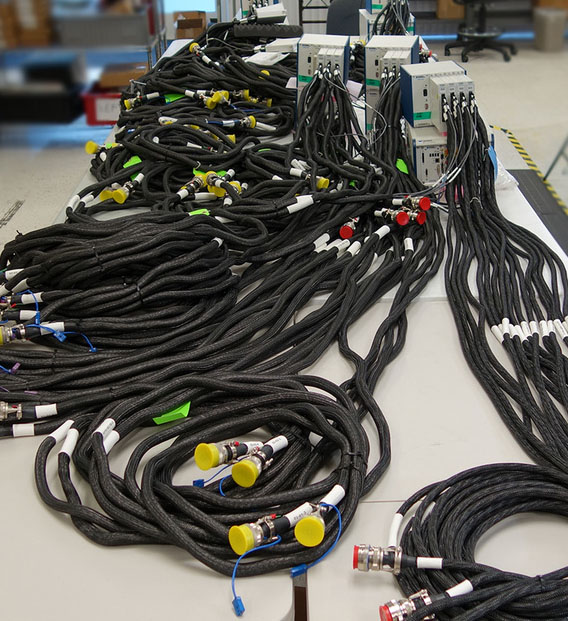

HARNESS PREPARATION

Cable harnesses are usually designed according to electrical requirements mainly comes in telecommunication and defence applications. A diagram is then provided (either on paper or on a monitor) for the assembly preparation and assembly.

The wires are first cut to the desired length, usually using a special wire-cutting machine. After this, the ends of the wires are stripped to expose the metal (or core) of the wires, which are fitted with any required terminals or connector housings.

In spite of increasing automation, hand manufacture continues to be the primary method of cable harness production in general, due to the many different processes involved, such as:

- Routing wires through sleeves,

- Taping with fabric tape, in particular on branch outs from wire strands,

- Crimping terminals onto wires, particularly for so-called multiple crimps(more than one wire into one terminal),

- Inserting one sleeve into another,

- Fastening strands with tape, clamps or cable ties.